Phone in Turkey

+90 539 893 40 01

Phone in Romania

+40 744 578 303

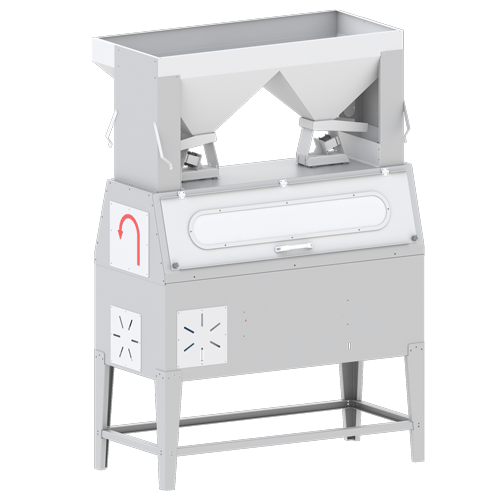

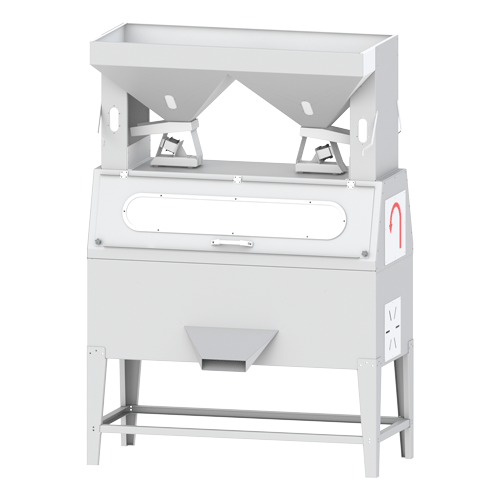

ALMOND SHELLER

Conditions before Shelling:

Almond Nut to be shelled, should have been cleaned from outer dry pulp & separated from admixtures*

For optimum hulling yield, your sales representative will explain you in detail required conditions.

Shelling Operation with Almond Sheller: Nuts is fed into the hopper and from hopper 2 Vibratory Linear feeders with VFD feeds Almond to the Sheller Cylinder. Shelling Drum forces the Almonds to pass through the grates where shelling occurs. For best yield Sizing of Almond Nut is required due to Shelling Grates being fixed sizes. Multilabel Shellers used for higher capacity operations.

An industrial duty machine, long lifetime ensured by rugged design ensures easily replaceable Impeller and hulling ring fabricated from a highly durable steel for wear resistance.

After Shelling Operation:

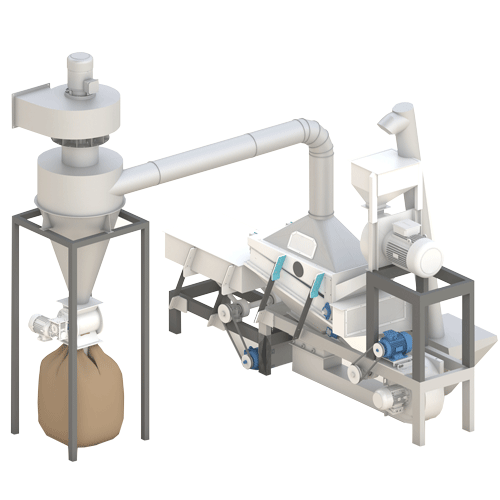

Almond Sheller breaks the shell of Almond Nut and output of machine Almond Shell, Almond Kernels and Almond In shell (none sheller) exists together. To obtain Almond Kernels there is sequence to do the separation of Almond Shell, Almond Kernels and Almond In shell. Your Sales representative will be happy to explain you what machines are used to obtain the expectable Kernel output.

Food Grade:

Easy access to all parts of the machine.

Food Grade painted surface is sufficient for Almond Seed processing equipment. Stainless Steel surface is optional.

Food Grade Lubricants for bearings.

Shelling yield:

Shelling yield ranges from 80 to 95 %, this high variation happens due to right conditions being provided or not and we are happy to share our experience. Please consult your sales agent.

Shipment:

If you are looking for single machine, we provide the Cargo parameters for each machine, so buyer can calculate Transport cost to delivery address and we will be more than happy to assist you in this matter please feel free to consult your sales agent.

Installation:

We supply technical documents and easy install videos to our clients for safe handling.

As well as our moto is ‘Plug and Play’ that makes our buyers experience much easier with Almond Sheller.

After Sales Support:

We have 7/24 online and on call After Sales Support Department.

For After sales parts purchasing you can go to our online saattechnologe.com or download our App to order your required spare part, if we have not opened an account for you, please go ahead open your account, purchase your part and it will get it delivered to your address.

Note: Capacities may vary for different impurity, moisture contents and seed verity.

ENVIRONMENTAL CONDITIONS

Environment Indoors

Temperature from -10°C to +40°C

Altitude Up to 1 000 m

NOISE

Sound pressure level, empty 79.2 dB(A)

Available Options

- An effective shell separation can be achieved with Shell Blower Fan

located at the outlet of the Almond Sheller.

Do you need more information?

You are always welcome to call, e-mail, or chat on WhatsApp

with our Sales Engineer Team to answer all your questions you

have in mind. We will do our utmost to revert as soon as

possible.

Saat Technologe exports to 70 countries on 4 continents. Consult any project you have in mind to benefit from our field experience. From Start-up, Turn Key Projects, to existing plant modifications; We are with you all the way.

FAQ

Saat Technologe provides 24 Months of warranty for all its Almond Sheller, please ask your Sales Engineer for the manufacturer’s Warranty Conditions.

Saat Technologe ‘s After Sales Support Team is ready for immediate support with Phone calls, online chat, and or video calls for all your technical needs for your Almond Sheller, You can ask for your user manual or look into your stand-by spare parts list provided by Saat Technologe.

All your questions about Almond Sheller like Capacity variations on which conditions, best conditions, application areas, Optional features, adjustment parameters, Before and after results, yield, work principle in greater detail, assembly variations, auxiliary equipment, Electrical parameters, Why to buy from Saat Technologe, What sets Saat Technologe apart from others, references, how many of these machines have been built and working, life Span and effecting matters, Spare parts and wear and tear parts, preventative maintenance, how to handle waste, how to handle dust if any, how to adapt to your Seed business whether be Farmer, Wholesaler, importer, exporter or Retailer, the value for Money, what are included what is excluded, transport cost, installation, and training, after-sales support, warranty conditions and any other topic you may relate to your business need, always happy to assist.

Phone in Turkey

+90 0539 893 40 01

Phone in Romania

+40 744 578 303