Phone in Turkey

+90 539 893 40 01

Phone in Romania

+40 744 578 303

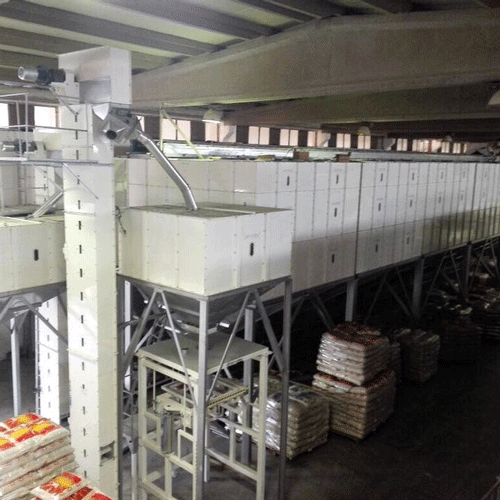

FILLING & WEIGHING ON LIFT

Saat Technologe Big Bag Filling & Weighing Scale on Lift is suitable for all sizes of FIBC Big Bags.

Frame and Structure: The Weighing System is built on a sturdy frame to provide support and stability during the filling process.

Weighing System: Big Bag Filler comes equipped with a weighing system to ensure accurate measurement and control of the quantity of material being filled into each bag.

Bag Support and Suspension: The System has a mechanism to support and suspend the big bag during filling. This may include hooks, straps, or other suspension devices.

Inlet and Outlet: There are openings for the material to enter the bag and exit once it’s filled. These openings are typically equipped with valves or spouts that can be controlled to regulate the flow.

Filler Spout: A filler spout is used to direct the material into the bag. It may be adjustable to accommodate different bag sizes.

Dust Collection System: Big Bag Filling and Weighing Systems include a dust collection system to minimize dust emissions during the filling process, ensuring a safer working environment.

Control Panel: A control panel allows operators to set parameters, monitor the filling process, and control various functions of the System.

Safety Features: Safety features such as emergency stop buttons, safety interlocks, and overload protection are often integrated into the System design to ensure safe operation.

Automation and Integration: Big Bag Filling and Weighing Systems are designed for automation and can be integrated into a larger production or processing line.

Material Compatibility: The design of the System is often adapted to handle specific types of materials, whether they are powders, granules, pellets, or other bulk forms.

Mobility and Portability: Big Bag Filling and Weighing Systems are designed to be mobile or portable, allowing for flexibility in their use within different locations or facilities.

Operation

- An Empty big Bag is hung from its 4 ears to the supplied frame, inlet spout is closed with a pneumatic Grip.

- Hung Big bag raised above the ground with Pneumatic Pistons.

- The Pre-set weight is activated with a push-bottom starter and the Pneumatic shutter opens.

- The pneumatic Flow Control shutter stops the seed flow into the big bag when the on-lift scale reaches the pre-set weight.

- The Filled & Weighed Big Bag goes down on the ground.

- The operator removes the full big bag with or without the pallet.

Content

- Suitable type of Conveyor to feed Pre-Storage Hopper

- Pre-storage hopper with Suitable Conical Hopper flow Control Pneumatic Shutter

- Big Bag Hanging Frame

- Big Bag Scale

- Power Panel

MODELS | BBFW on LIFT |

Weighing Range | 0-2000KG |

Weighing Accuracy | ± % 0.1 |

Bag Type | FIBC |

Weighing Capacity | 1000 Kg – 20 Bags/Hour |

Air Pressure | 5-6 Bar |

Air Consumption | 20 Litre/Minute |

Power Supply | 3 Ph, 380 VAC /50-60 Hz |

Do you need more information?

You are always welcome to call, e-mail, or chat on WhatsApp

with our Sales Engineer Team to answer all your questions you

have in mind. We will do our utmost to revert as soon as

possible.

Saat Technologe exports to 70 countries on 4 continents. Consult any project you have in mind to benefit from our field experience. From Start-up, Turn Key Projects, to existing plant modifications; We are with you all the way.

FAQ

Saat Technologe provides 24 Months of warranty for all its Filling & Weighing On Lift, please ask your Sales Engineer for the manufacturer’s Warranty Conditions.

Saat Technologe ‘s After Sales Support Team is ready for immediate support with Phone calls, online chat, and or video calls for all your technical needs for your Filling & Weighing On Lift, You can ask for your user manual or look into your stand-by spare parts list provided by Saat Technologe.

All your questions about Filling & Weighing On Lift, like Capacity variations on which conditions, best conditions, application areas, Optional features, adjustment parameters, Before and after results, yield, work principle in greater detail, assembly variations, auxiliary equipment, Electrical parameters, Why to buy from Saat Technologe, What sets Saat Technologe apart from others, references, how many of these machines have been built and working, life Span and effecting matters, Spare parts and wear and tear parts, preventative maintenance, how to handle waste, how to handle dust if any, how to adapt to your Seed business whether be Farmer, Wholesaler, importer, exporter or Retailer, the value for Money, what are included what is excluded, transport cost, installation, and training, after-sales support, warranty conditions and any other topic you may relate to your business need, always happy to assist.

Phone in Turkey

+90 0539 893 40 01

Phone in Romania

+40 744 578 303