Phone in Turkey

+90 539 893 40 01

Phone in Romania

+40 744 578 303

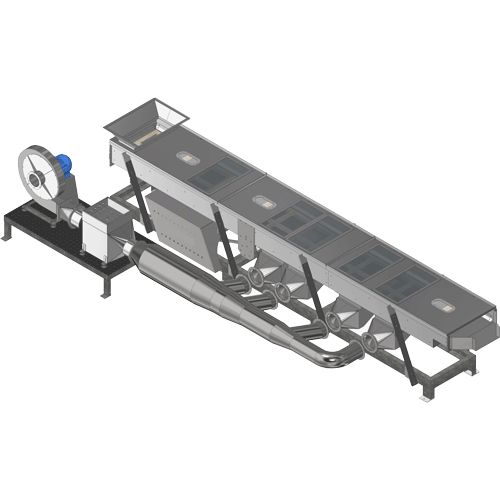

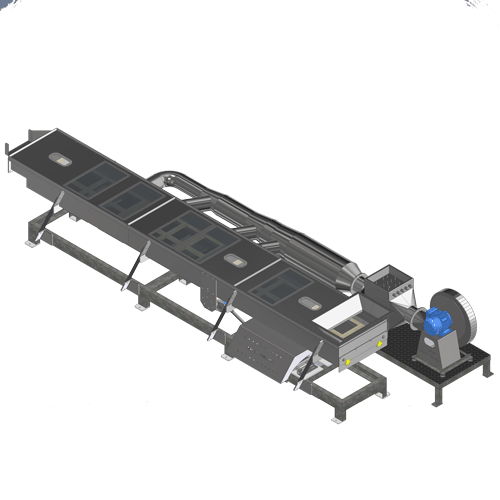

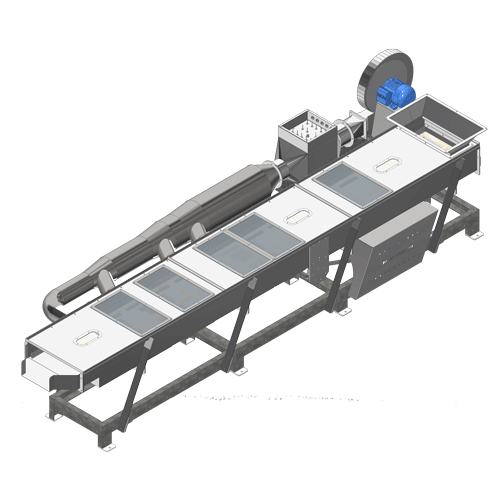

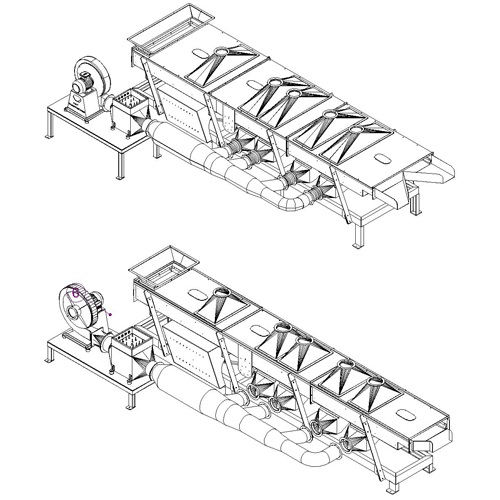

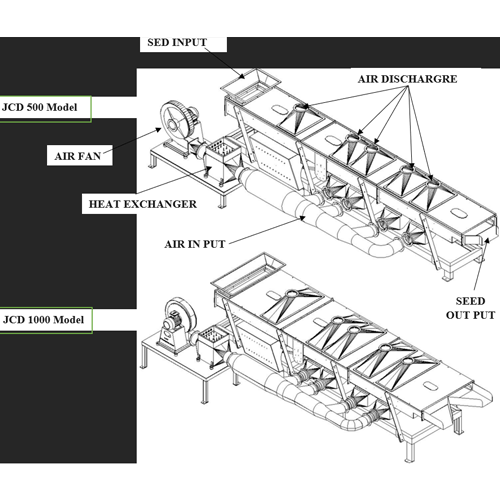

FLUID BED AIR DRYER

Application

The jog conveyor has a wide range of application and construction and can be used for conveying, cleaning, grading and drying grain (for example, coated or dressed materials) and similar products.

Working mode

The jog conveyor dryer works by the action of the eccentric shaft which, via connecting rods, causes the conveyor to move backwards and forwards, which the results in the movement of the material via the coiled suspension units. The jog conveyor dryer transports material slowly and empties the material at the outlet /outlets.

In order to facilitate drying processes, the machine is constructed with a perforated screen system.

JCD designed with heating sections, and screening sections. Each of the heating sections is supplied

separately with warm air, by using heaters and blowers below the jog conveyor dryer.

Each screening section consists of single screens with connection spout DM120 mm for aspiration.

The main drive is a 4 kW – squirrel cage motor (standard 3/PE 400V 50Hz). The operation of the drive must be by frequency inverter (not included with the jog conveyor dryer).

Technical data | Type JCD | 500 | ||

Length in Meters | 6+2 | 5+1 | 3+1 | |

Motor (standard) | kW | 4 | 4 | 4 |

Air requirement | m3/h | 21 000 | 10 000 | 6 000 |

Dimensions | mm | |||

Length |

| 7 860 | 6 860 | 4 858 |

Width | 1 590 | 1 590 | 1 590 | |

Height | 945 | 945 | 945 | |

Net weight | kg | 1 350 | 1050 | 796 |

Dynamic loading at 6 Hz N | ||||

PH= | +/-300 | +/-230 | +/-180 | |

PV= | +/-1 200 | +/-950 | +/-600 | |

Technical data |

| Type JCD | 1000 | |

6+2 | 5+1 | 3+1 | ||

Motor (standard) | kW | 4 | 4 | 4 |

Air requirement | m3/h | 21 000 | 10 000 | 6 000 |

Dimensions | mm | |||

Length |

| 7 905 | 6 310 | 4 670 |

Width | 1 360 | 1 360 | 1 360 | |

Height | 1 850 | 1 850 | 1 850 | |

Net weight | kg | 3 800 | 2 500 | 1 900 |

Dynamic loading at 6 Hz N | ||||

PH= | +/-300 | +/-230 | +/-180 | |

PV= | +/-1 200 | +/-950 | +/-600 | |

Do you need more information?

You are always welcome to call, e-mail, or chat on WhatsApp

with our Sales Engineer Team to answer all your questions you

have in mind. We will do our utmost to revert as soon as

possible.

Saat Technologe exports to 70 countries on 4 continents. Consult any project you have in mind to benefit from our field experience. From Start-up, Turn Key Projects, to existing plant modifications; We are with you all the way.

FAQ

Saat Technologe provides 24 Months of warranty for all its Fluid Bed Dryer, please ask your Sales Engineer for the manufacturer’s Warranty Conditions.

Saat Technologe ‘s After Sales Support Team is ready for immediate support with Phone calls, online chat, and or video calls for all your technical needs for your Fluid Bed Dryer, You can ask for your user manual or look into your stand-by spare parts list provided by Saat Technologe.

All your questions about Fluid Bed Dryer like Capacity variations on which conditions, best conditions, application areas, Optional features, adjustment parameters, Before and after results, yield, work principle in greater detail, assembly variations, auxiliary equipment, Electrical parameters, Why to buy from Saat Technologe, What sets Saat Technologe apart from others, references, how many of these machines have been built and working, life Span and effecting matters, Spare parts and wear and tear parts, preventative maintenance, how to handle waste, how to handle dust if any, how to adapt to your Seed business whether be Farmer, Wholesaler, importer, exporter or Retailer, the value for Money, what are included what is excluded, transport cost, installation, and training, after-sales support, warranty conditions and any other topic you may relate to your business need, always happy to assist.

Phone in Turkey

+90 0539 893 40 01

Phone in Romania

+40 744 578 303