Phone in Turkey

+90 539 893 40 01

Phone in Romania

+40 744 578 303

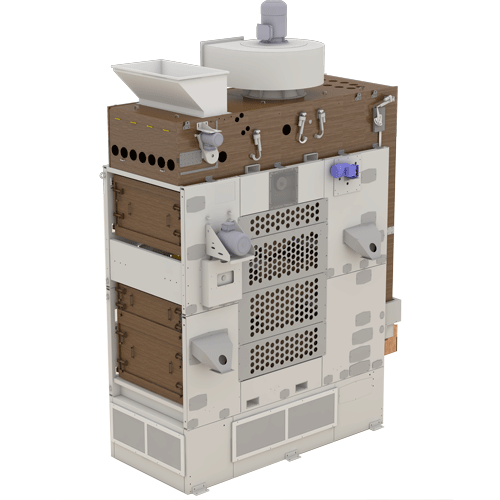

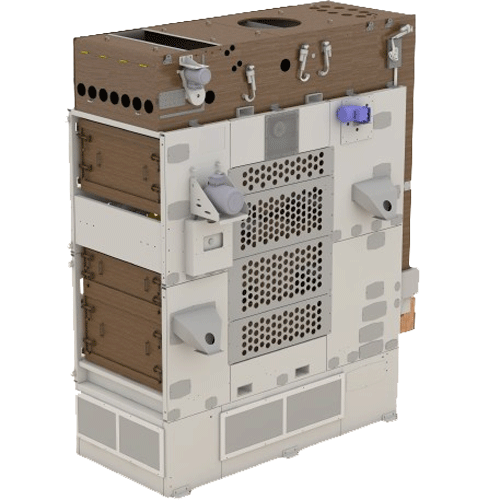

OMEGA 206 SUPER FINE SEED SCREEN CLEANER

Saat Technologe has a complete line-up of precise cleaners to remove impurities. The gentle cleaning process helps maintain seed quality and germination potential by minimizing damaged seeds. Our experts work with you to understand your business and make sure you have the right systems for your production. Saat Technologe ‘s Optimum series pre-cleaners, cleaners, and graders are easy to use and efficient to improve your productivity and profitability.

Gentle handling of products is key to meet your expectations for quality and hit your operational goals. Saat Technologe’s equipment is specifically designed to respect your harvest and increase your production efficiency, with the ultimate goal to prepare your product for better storage.

Saat Technologe’s Optimum Fine Cleaners are designed to separate light impurities and small seeds from dry products, like grains, maize, oil seeds, legumes and similar.

Using a combination of flat reciprocating screens and two or three air systems, Optimum fine-cleaners are estimated to remove approximately 85% of impurities. This reduces impurities from 4% to 0.5%. It is also estimated to remove approximately 75% of small seeds. This reduces small seeds from 8% to approximately 2% after cleaning.

OPTIMUM 206 CLEANER FEATURES

- Full-width Vibratory

– has stepless adjustment of the feed rate by an inverter.

– separate control panel ensures a uniform flow over the entire width of the sieve- is self-cleaning

– improves the air cleaning considerably as the product hits the pre-suction area uniformly

– is careful to leguminous seeds, beet seeds etc.

– ensures optimal capacity utilisation of the machine

– has no down time due to choked up inlet

– requires no cleaning in connection with changing products

- Pre and After Suction System

-is built as separate systems to ensure a precise and independent air cleaning

-Separates the light particles before the material reaches the sieves

-improves the cleaning effect and results in a higher capacity

-Ensures an excellent purity of the product due to the suction of light particles such as empty seeds, husks, dust etc. When the product leaves the cleaner via the air screen.

- Change of Product Flow

-makes many different product flows possible according to the capacity, product, number of fractions etc.

-by means of six different diagrams in the cleaner ensures excellent purity and minimum waste

– is easily done by changing the size of the sieves and the position of the outlet trays

4.Perforated Screens

– are available with round and long holes from 0,3 to 25,0mm

– are also available as wire mesh screens are also available as screen plates with very little tolerance which ensures a minimum cleaning loss.

– Are available in a standard size of: 800 mm (L) x 1250 mm (B) = 1 m

5.Screenshoes of Birch Plywood

-are moisture and insect-resistant

-are constructed with replaceable wear plates and sieve runners in exposed areas

– have a long lifetime because the birch plywood easily tolerates the vibrations of the screen shoes -give less resonance owing to the birch plywood and thus a better working environment is obtained

- Balanced Eccentric System

– is fitted with counter weights ensuring steady running

-involving minimum stress on buildings and steel structures

-is fitted with ‘’heavy duty’’ bearings

-ensures maximum utilisation of the cleaning effect of the sieves owing to accurately attuned stroke and RPM

7.Ball Box

– ensures efficient cleaning of sieves by means of rubber balls

– can maintain the cleaning effect at extremely low temperatures as the rubber balls are cast in a very suitable material

– is cast solid so that it prevents stuck seeds etc.(self-cleaning)

– is separately mounted in the screen shoes which ensures a quick change of sieves without removing the ball boxes

- Air Lifting Channel

-eliminates light seeds in the variable expansion chamber

-through which husks, dust etc. are led with the airflow to the after-suction system.

-is available with an extra-large expansion chamber and centre outlet for special processes

- Screw Conveyor for Light Waste

– ensures continuous discharge of dust and light waste from the air system via screws

– with finger flaps to ensure optimal dust separation in the expansion chamber by preventing false air from entering into the chamber

10.Air Lifting Sieve Screen

-serves to convey the product through the air flow to ensure elimination of light particles

-forces the product through under passage to turn its biggest surface against the air flow in order to obtain optimal separation

– is constructed with adjustable air lifting hood over the air lifting sieve, which ensures optimal collecting up of the discarded light particles

– is combined with air lifting hood, designed with inspection window in full width, in order to make the adjustment of the air volume easier.

11.Air Lifting Unit

-is capable-by means of staggered fans and air guides-of giving a completely uniform air pressure from beneath the product when it leaves the cleaner

-ensures a complete blow through of the product which causes an elimination of light seeds, husks, straw and dust

-with specially designed impellers ensuring low noise level

-has stepless adjustment of RPM on the fans

Do you need more information?

You are always welcome to call, e-mail, or chat on WhatsApp

with our Sales Engineer Team to answer all your questions you

have in mind. We will do our utmost to revert as soon as

possible.

Saat Technologe exports to 70 countries on 4 continents. Consult any project you have in mind to benefit from our field experience. From Start-up, Turn Key Projects, to existing plant modifications; We are with you all the way.

FAQ

Saat Technologe provides 24 Months of warranty for all its Omega 206 Super Fine Seed Screen Cleaner, please ask your Sales Engineer for the manufacturer’s Warranty Conditions.

Saat Technologe ‘s After Sales Support Team is ready for immediate support with Phone calls, online chat, and or video calls for all your technical needs for your Omega 206 Super Fine Seed Screen Cleaner, You can ask for your user manual or look into your stand-by spare parts list provided by Saat Technologe.

All your questions about Omega 206 Super Fine Seed Screen Cleaner like Capacity variations on which conditions, best conditions, application areas, Optional features, adjustment parameters, Before and after results, yield, work principle in greater detail, assembly variations, auxiliary equipment, Electrical parameters, Why to buy from Saat Technologe, What sets Saat Technologe apart from others, references, how many of these machines have been built and working, life Span and effecting matters, Spare parts and wear and tear parts, preventative maintenance, how to handle waste, how to handle dust if any, how to adapt to your Seed business whether be Farmer, Wholesaler, importer, exporter or Retailer, the value for Money, what are included what is excluded, transport cost, installation, and training, after-sales support, warranty conditions and any other topic you may relate to your business need, always happy to assist.

Phone in Turkey

+90 0539 893 40 01

Phone in Romania

+40 744 578 303