Phone in Turkey

+90 539 893 40 01

Phone in Romania

+40 744 578 303

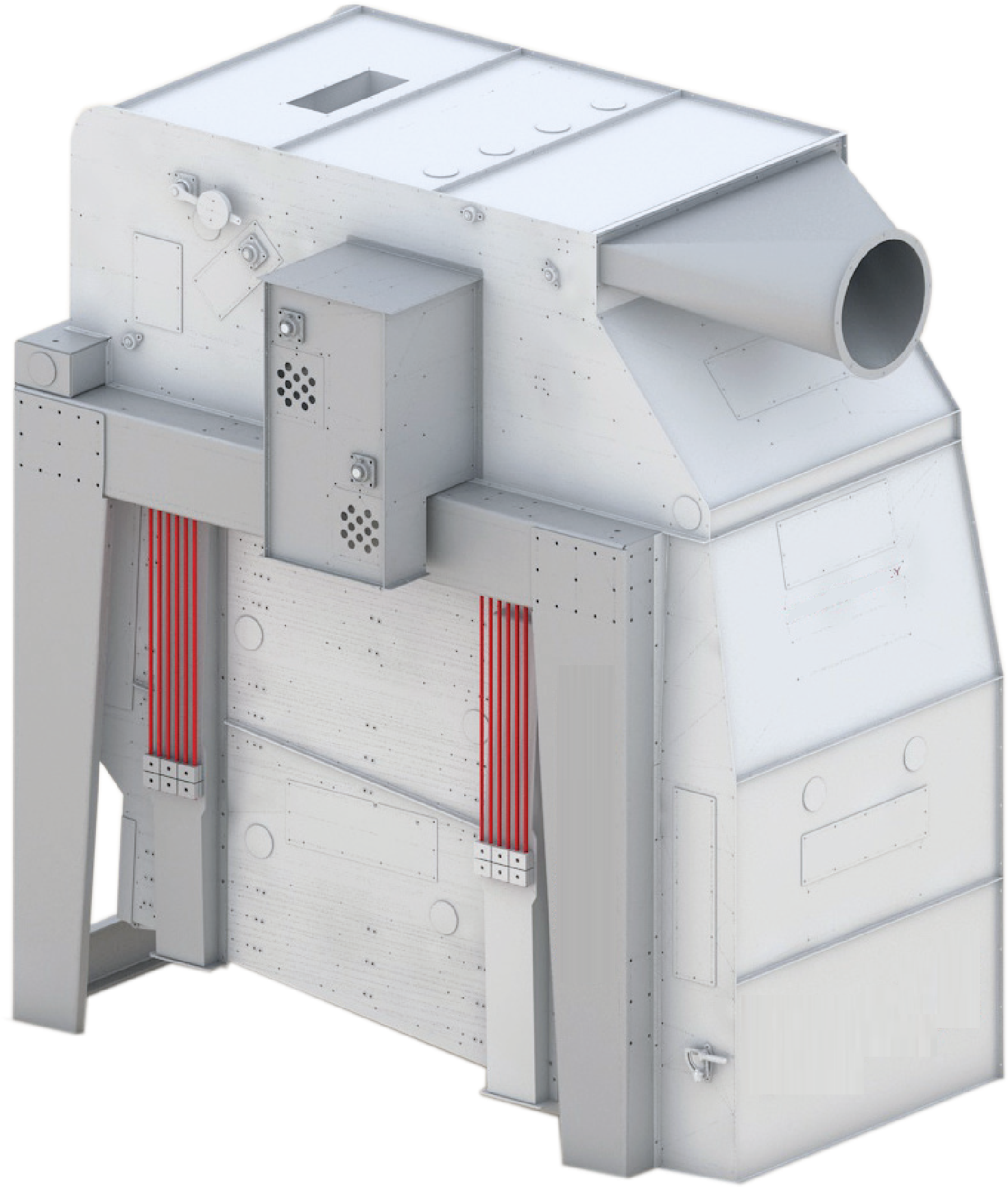

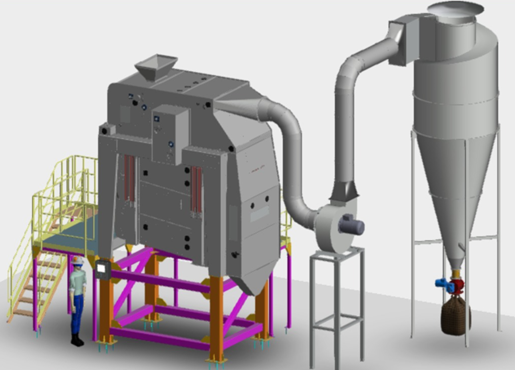

OSCILLATING SEED PRE-CLEANERS

For more than 15 years, Saat Technologe has been something of a fixed institution in the development, design and production of cleaning and grading machines. Throughout the decades, we have left a significant impact on the technical standard of these systems. Especially when it comes to harvest crop intake systems as well as pre-cleaning and main cleaning systems for cereal grains, maize, oilseeds, legumes, malt, rice, coffee and soybeans a wide range of users are relying on technology made by Saat Technologe.

Our high-performance machines are used mainly in

- Harvest crop intake and receipt facilities delivery pre-cleaning operations

- Mills and malting plants

- Silos and storage warehouses

- Seed processing plants

These machine types, although vastly different from one another, have one important thing in common: Anyone opting for one of the ORION series cleaning and grading machines will get thousand fold proven technology for cleaning cereal grains, oilseeds and legumes and for processing malting barley, malt and seed grains. And a tried-and-true system with air classification at the infeed end and high-intensity vertical sifting at the outfeed end. These cleaning systems are being put to the test every day by countless companies all over the world.

Cleaning machines have been one of Saat Technologe ‘s core products right from the outset. In critical dialogue with our customers and partners, we have been constantly receiving and implementing requests and suggestions and responded to market demands with well-targeted developments. The logical result: today’s state-of-the-art ORION series cleaning machines, which leave nothing to be desired, thanks to their functional details and holistic, tailor made concepts. Quality shows in a number of features, such as e.g.:

- State-of-the-art technology based on decades of experience in the development of high-quality threshing-crop cleaning machines

- Double aspiration thanks to vertical sifters at the infeed and outfeed ends, for high-intensity, economical and environmentally-friendly cleaning through air separation of the fine particles

- High hourly output rates thanks to large screen surfaces, even for very contaminated or wet products

- Economical solution for processing one or two different product types without need of screen change

- Optimized system adaptability to the cleaned product thanks to air volume regulation – either by remote control or directly „hands-on“

- Minimum maintenance thanks to optimized design and use of high-quality components

APPLICATION & CHARACTERISTICS

Cleaning machines of the ORION 22A, 222A, 333A and 2222A series are worldwide proven universal cleaning machines for single or double product sorting without need of screen exchange. They have been developed specifically for handling di cult products such as e.g. rape, and are used primarily in silo and processing plants as well as in storage warehouses and malting plants.

Main features

* Economical and highly efficient cleaning system thanks to the twice-over use of the aspiration air

* High output rates thanks to the time-tested plan sifter system with circular vibratory movements

* Cleaning and grading through course- and grain screens into

4 fractions:

Fraction 1 = Accept seed

Fraction 2 = Undersize Admixtures Waste

Fraction 3 = Oversize Admixtures

Fraction 4 = Infeed and outfeed aspiration lightweight Admixtures

* High operational reliability thanks to screens with perforated metal plates on rugged steel frames and time-tested rubber ball cleaning system

ORION PRE-CLEANER FEATURES

1- Product inlet with vibrating tray for the uniform and gentle distribution

of the product across the entire machine width.

2- Inlet Aspiration: removes lightweight particles and dust from seed, which reduces the sieve load and increases the cleaning quality

3- Screen door: easiest access to all screen layers in no time.

4- Over size Screen layers: reliable removal of course or bigger particles.

5- Under size screen layers: precise separation in; 1st grade (accept product) and 2nd grade (broken, sand, small grain,

6- Rubber ball screen cleaning under all screen area.

7- Flywheel and brake motor: drive designed for continuous operation which ensures the gentle circular movement of the sieve box according to the proven plan sifter principle.

8- Oscillation monitor: safety equipment that leads to the immediate shutdown of the sieving machine in case of irregular screen box movement and thus ensures safe operation.

9- Exhaust air connection: guides the dusty air to the connected de-dusting system to ensure clean air in the machine

10- Aspiration Chamber with discharge screws: discharge of light material from inlet and outlet aspiration to reduce the filter load and to provide a perfect checking point for aspiration settings.

11- Polyamide rods: safe suspension of the sieve box without the transmission of vibrations onto the sieve frame; with special shape for easy installation Vertical sifter / 12- Outlet aspiration: integrated, easy to adjust and illuminated aspiration channel with large inspection windows for optimal adjustment of the air volume to the product.

13- Dust -proof rubber cover: for quick and easy maintenance and accessibility to the interior of the machine.

Do you need more information?

You are always welcome to call, e-mail, or chat on WhatsApp

with our Sales Engineer Team to answer all your questions you

have in mind. We will do our utmost to revert as soon as

possible.

Saat Technologe exports to 70 countries on 4 continents. Consult any project you have in mind to benefit from our field experience. From Start-up, Turn Key Projects, to existing plant modifications; We are with you all the way.

FAQ

Saat Technologe provides 24 Months of warranty for all its Oscillating Seed Pre-Cleaners, please ask your Sales Engineer for the manufacturer’s Warranty Conditions.

Saat Technologe ‘s After Sales Support Team is ready for immediate support with Phone calls, online chat, and or video calls for all your technical needs for your Oscillating Seed Pre-Cleaners, You can ask for your user manual or look into your stand-by spare parts list provided by Saat Technologe.

All your questions about Oscillating Seed Pre-Cleaners like Capacity variations on which conditions, best conditions, application areas, Optional features, adjustment parameters, Before and after results, yield, work principle in greater detail, assembly variations, auxiliary equipment, Electrical parameters, Why to buy from Saat Technologe, What sets Saat Technologe apart from others, references, how many of these machines have been built and working, life Span and effecting matters, Spare parts and wear and tear parts, preventative maintenance, how to handle waste, how to handle dust if any, how to adapt to your Seed business whether be Farmer, Wholesaler, importer, exporter or Retailer, the value for Money, what are included what is excluded, transport cost, installation, and training, after-sales support, warranty conditions and any other topic you may relate to your business need, always happy to assist.

Phone in Turkey

+90 0539 893 40 01

Phone in Romania

+40 744 578 303