Phone in Turkey

+90 539 893 40 01

Phone in Romania

+40 744 578 303

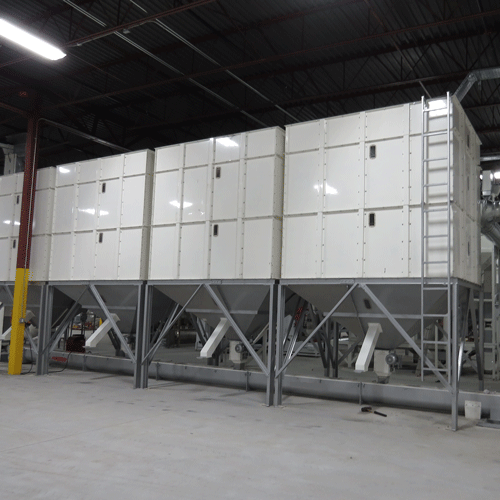

SQAURE SILOS

Indoor Square Silos are designed and manufactured for food processing and or industrial plant product storage purposes.

Saat Technologe designs, and manufactures helper equipment for square silos usage purposes i.e., product feeding elevators, product easy down, capacity sensors, mechanical outlet valves, pneumatic valve outlets, capacitive measurement outlets, second outlet (for big bag filling i.e.) magnetic feeders, cooler and heaters, air ventilator.

Wall Sheets for the bins are manufactured from suitable material for customer demand hot galvanized steel sheets, Stainless Steel, Owen Coated Painted ST 37 Carbon Steel Sheets which are Laser Cut for maximum rigidity obtained. Accurate processes on the production line ensure a tight fit and easy erection. Depending on wall element length and what total height bins will have to be, different sheet thicknesses have to be selected.

Sensor

Capacity or level sensors can be designed and supplied as an option with silos. Capacity or level sensors can be designed and supplied as an option with silos.

Inspection Window

The acrylic window allows visual inspection of the level of stored product.

Tie Rods: By using tie rods, larger bins can be supported. This is done by installing steel pin supports across to walls. They are delivered in corresponding lengths to the wall sheets.

Loadcells

Weighing of stored goods in Silo and using this data is an available feature.

Corner Posts:

Corner posts are available in 2 designs according to the illustrations.

Type 1- where four walls are jointed together with Nut Bolt and Washer Joints Type 2-Square profile steel bars welded where four walls are joined together. The posts are available as standard painted or hot-dipped galvanized. Apart from the standard posts above, there are several posts for special purposes, for instance, when hoppers are fitted.

Nut, Bolt & Washer

Bolts, washers, and Nuts are used for assembling the wall part and joining corner posts and wall sheets, flanged bolts M8 and nuts galvanized, are used No washers are necessary because of the flanged nuts. This gives an easier erection.

Second Outlet

Easy discharge of excess product from the silo into i.e. a big bag, elevator hopper, or conveyor belt. Ultrasonic Sensor

Ultrasonic Sensors measure the distance or presence of a target object by sending a pulsed ultrasound wave at the object and then measuring the time for the sound echo to return. Knowing the speed of sound, the sensor can determine the distance of the object and the distance measurement is equal to the capacity used in the silo.

Lid/Cover

The Silo lid keeps the stored product safe from external contamination possibilities. Safe and Healthy Storing at maximum.

Lid/Cover Entrance

Provides Entrance for operator inside of Silo for cleaning, service and maintenance.

Ladder Outside and Inside

Provides access inside of the silo for cleaning, service, and maintenance.

Hopper Vibrator; Developed to facilitate flow from bins and hoppers on all types of materials, including large aggregate and sand, fine powders, flakes, pills, bottle caps, and just about any material that tends to stick or clog inside a silo.

Outlet Valves

Silos are supplied with manual operated outlet valves in its standard for product/seed discharge control system. As an option manual operated ball bearing equip outlet valves or auto controlled pneumatic outlet valves are available upon request.

Support Frames/Legs

According to required discharge heights Support Frames designed and provided suitably.

Easy Down

For fragile seeds, free fall speed is reduced with ‘Easy Down’ feature, located in the centre of inner Silo staring from intake and to the bottom of the silo.

Do you need more information?

You are always welcome to call, e-mail, or chat on WhatsApp

with our Sales Engineer Team to answer all your questions you

have in mind. We will do our utmost to revert as soon as

possible.

Saat Technologe exports to 70 countries on 4 continents. Consult any project you have in mind to benefit from our field experience. From Start-up, Turn Key Projects, to existing plant modifications; We are with you all the way.

FAQ

Saat Technologe provides 24 Months of warranty for all its Sqaure Silos, please ask your Sales Engineer for the manufacturer’s Warranty Conditions.

Saat Technologe ‘s After Sales Support Team is ready for immediate support with Phone calls, online chat, and or video calls for all your technical needs for your Sqaure Silos, You can ask for your user manual or look into your stand-by spare parts list provided by Saat Technologe.

All your questions about Sqaure Silos, like Capacity variations on which conditions, best conditions, application areas, Optional features, adjustment parameters, Before and after results, yield, work principle in greater detail, assembly variations, auxiliary equipment, Electrical parameters, Why to buy from Saat Technologe, What sets Saat Technologe apart from others, references, how many of these machines have been built and working, life Span and effecting matters, Spare parts and wear and tear parts, preventative maintenance, how to handle waste, how to handle dust if any, how to adapt to your Seed business whether be Farmer, Wholesaler, importer, exporter or Retailer, the value for Money, what are included what is excluded, transport cost, installation, and training, after-sales support, warranty conditions and any other topic you may relate to your business need, always happy to assist.

Phone in Turkey

+90 0539 893 40 01

Phone in Romania

+40 744 578 303