Phone in Turkey

+90 539 893 40 01

Phone in Romania

+40 744 578 303

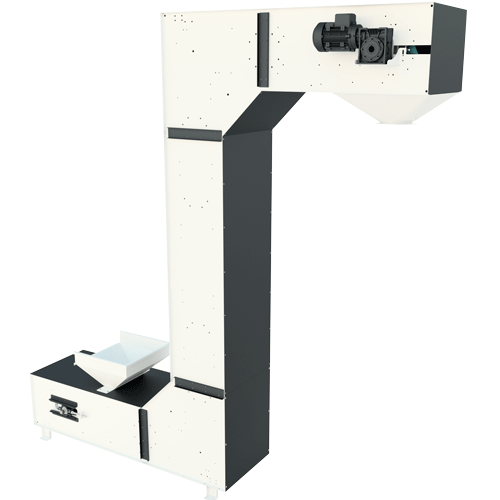

PENDULUM BUCKET ELEVATOR

General

Brand Saat Technologe

Designation Pendulum Bucket Z Elevator

Model PBE Series

Application The Perfect Elevator for your specific application due to Unique Modular Design.

Application and Function

Pendulum bucket elevators are used for very gentle vertical conveying of all kinds of granular product. Especially on the seed sector, they are the most suitable conveyors. They can also manage big horizontal distances, thus being able to replace the combination of belt conveyor and normal bucket elevator.

The incoming product is fed to the pendulum bucket elevator continuously and very gently by means of a vibratory feeder. The edges of the buckets overlap each other in the inlet section and therefore prevent spillage of kernels. Due to the pivoted mounting of buckets in the chain, buckets keep their horizontal position all through the way around in the conveyor until they finally reach the outlet. There, each bucket is tilted and the product falling out is gently led into the outlet hopper.

The pendulum bucket elevator can be equipped with a number of several inlets and outlets. Inlets can work at the same time, while outlets are used singular, meaning only one outlet being active momentarily.

The pendulum bucket elevators produced by Saat Technologe can be delivered in three types, depending on the amount of product to be transported. This conveyor has the big benefit of combining both horizontal and vertical transport in one machine. Adding the very gentle way of transporting, the pendulum bucket elevator is the perfect conveyor for seeds and other sensible products. By means of using different speeds, there’s a wide range of different hourly capacities that can be reached.

Saat Technologe pendulum bucket elevators are designed modularly and are normally painted. On request, galvanized or powder coated surfaces are also possible.

- Tensioning station: This station is situated in the foot section as the first part. By means of turning a spindle, the tension of the chain carrying the buckets is easily adjustable.

- Inlet section: The overlapping of the buckets in this section grants that all product inserted will go into the buckets passing by without any loss. Generally, a vibratory feeder should be used before the inlet to guarantee a harmonious filling of the buckets. The installation of several inlets is possible.

- Intermediate sections: The vertical and horizontal slots are delivered in a standard length. To reach the correct heights and lengths of the system, fitting pieces with specific lengths for each order are attached. The connection of the slots with each other and with the other stations is done by means of flanges that are screwed with each other.

- Corner sections: These corners sections can either form an “L” or a “T” , thus being able to form various transport lines.

- Outlet section: During the whole way through the pendulum bucket elevator, the buckets are always in a horizontal position. Only in the outlet section, the buckets are tilted by a lever that can also be operated pneumatically if several outlet stations are installed. In this case, one of the outlets is activated, all the others are not in operation and the buckets pass them by in horizontal position. The total rotation of the bucket at the outlet guarantees a complete emptying.

- Drive section: This is the last station in the system. The gear motors have torque control (=overload protection) and a brake. Speed guard and variable speed are available on request. It is necessary to use a soft starter. Braking must happen temporally delayed after stopping the feeder.

- Buckets: The buckets are made of plastic that can be food safe and antistatic on request. Stainless steel buckets and automatic bucket- cleaning system are also available.

- Chain: The metal chain grants long life and is easy to assemble by means of using simple master links. The buckets can be taken off the chain without any tools, therefore changing of buckets is very easy.

Technical data | |||||||||||||||

Type | Capacity | A | B | C | D | E | F | G | H | I | J | K | L | M | |

PBZE 150 | 10 m³/h | mm | 766 | 1000 | 500 | 440 | 500 | 975 | 650 | 570 | 300 | 500 | 800 | 750 | 210 |

PBZE 300 | 20 m³/h | mm | 937 | 1200 | 500 | 569 | 500 | 1232 | 844 | 870 | 350 | 630 | 1084 | 1100 | 355 |

PBZE 500 | 40 m³/h | mm | 710 | 952 | 3672 | 4050 | 2200 | 3321 | 530 | 2000 | 250 | 1995 | 630 | 844 | 100 |

Do you need more information?

You are always welcome to call, e-mail, or chat on WhatsApp

with our Sales Engineer Team to answer all your questions you

have in mind. We will do our utmost to revert as soon as

possible.

Saat Technologe exports to 70 countries on 4 continents. Consult any project you have in mind to benefit from our field experience. From Start-up, Turn Key Projects, to existing plant modifications; We are with you all the way.

FAQ

Saat Technologe provides 24 Months of warranty for all its Pendulum Bucket Elevator, please ask your Sales Engineer for the manufacturer’s Warranty Conditions.

Saat Technologe ‘s After Sales Support Team is ready for immediate support with Phone calls, online chat, and or video calls for all your technical needs for your Pendulum Bucket Elevator, You can ask for your user manual or look into your stand-by spare parts list provided by Saat Technologe.

All your questions about Pendulum Bucket Elevator like Capacity variations on which conditions, best conditions, application areas, Optional features, adjustment parameters, Before and after results, yield, work principle in greater detail, assembly variations, auxiliary equipment, Electrical parameters, Why to buy from Saat Technologe, What sets Saat Technologe apart from others, references, how many of these machines have been built and working, life Span and effecting matters, Spare parts and wear and tear parts, preventative maintenance, how to handle waste, how to handle dust if any, how to adapt to your Seed business whether be Farmer, Wholesaler, importer, exporter or Retailer, the value for Money, what are included what is excluded, transport cost, installation, and training, after-sales support, warranty conditions and any other topic you may relate to your business need, always happy to assist.

Phone in Turkey

+90 0539 893 40 01

Phone in Romania

+40 744 578 303