Phone in Turkey

+90 539 893 40 01

Phone in Romania

+40 744 578 303

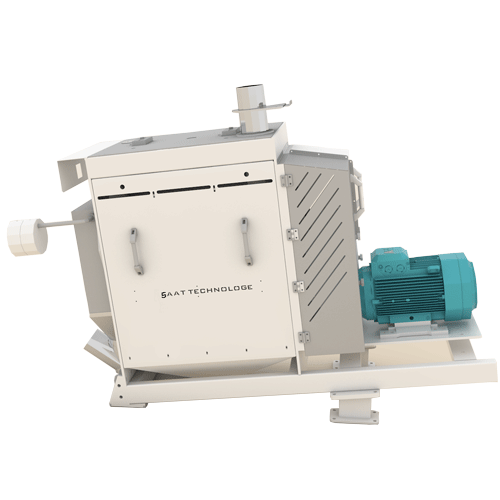

ABRASIVE HULLER

Delivering high yields and an optimum finish.

Designed for the modern pulse and grain mills

The Abrasive ROLLER huller is designed for the efficient removal of husks from a wide range of pulses. This high capacity processing solution provides improved yields, uniform finish and optimum quality while reducing overall processing costs.

Developed exclusively for pulse processing, the ROLLER huller gives processors precise control over hulling conditions. Due to the easy setting of the grinding gap, the adjustable machine inclination and the pressure control within the peeling chamber, ROLLER huller offers high peeling efficiency, less breakage and an optimal finish. Its robust design contributes to less wear and tear and longer service life. In combination with low dust generation, this leads to improved productivity and safe and hygienic processing, an improved productivity and safe and hygienic processing is being ensured.

High quality hulling with uniform finish.

For a broad range of pulse varieties.

High yield and throughput

The optimized feed and machine angle ensure a seamless transport of the pulses into the hulling chamber, resulting in high processing capacities and effective hulling. The hulling unit consists of four individual sections and a new screen assembly. Both contribute to an even hulling gap and a constant peeling performance.

Maximum service life

Abrasive ROLLER huller is designed to minimize damage caused by abrasive by-products that occur during hulling. This improves the service life of the machine and ensures maximum uptime.

Hygienic and easy operation

Abrasive ROLLER huller is designed without dead spots for product deposits and thus ensures hygienic operation. The huller can be operated intuitively with simple control elements and offers a quick product change due to the good accessibility of the product area. This also facilitates and accelerates cleaning and maintenance.

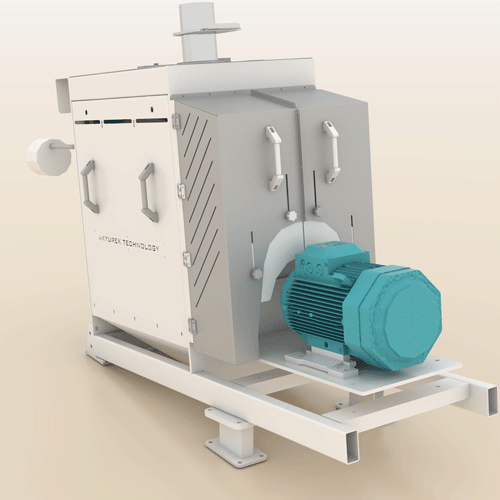

Working Principle

Whole pulses are fed into the inlet spout [A], which is directed towards the hulling chamber [B]. The pulses are hulled as they pass between the screens [C] and the grinding stones [E] rotating on the shaft [D]. The inclination of the machine causes the peeled product to leave the peeling chamber through the outlet chamber [F]. The separated husk passes through the sieves into the hopper [G].

Benefits

– High yield and optimal finish on hulled pulses

– Designed for easy and hygienic operation

– Maximum service life

– Wide range of applications

Stable, balanced machine design with large hulling surface area

Delivers higher capacity and uniformed hulling performance.

Specially designed hulling stones

Saat Technologe proprietary emery stones are designed in eleven sections for minimal wear and when needed, are easy to replace.

New sieve assembly with three sieve sets (optional)

Easily replaceable concentric sieves are available as an option to help maintain a uniform hulling area throughout the stones life cycle.

Variety of emery stones and grit sizes

Specially selected and recommended by Saat Technologe technologists to deliver optimum hulling degree and lower brokens.

Maximum hygiene

Food grade rubber seals between stones reduces product accumulation, dust and allows for easier cleaning to reduce contamination during product changeovers.

Adjustable milling parameters

Maximum control on hulling degree through adjustable hulling gap and pressure.

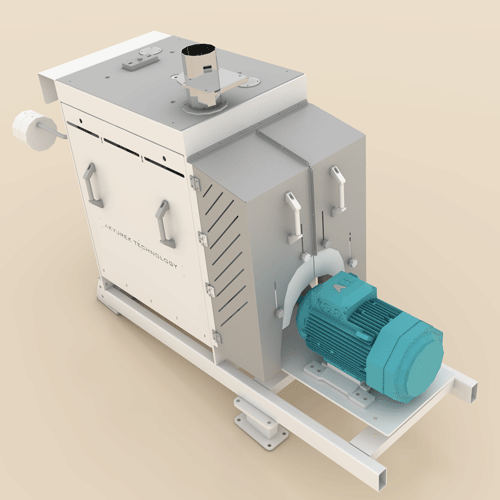

Adjustable machine inclinations

Easy to change inclination to suit variations in input products.

Connections to aspiration system

Connections to convey husk pneumatically are available as an option for a cleaner operation.

CE certified

Abrasive ROLLER huller is designed and manufactured to conform to the highest process and safety standards.

APPLICATION AREAS

- Brown Lentil Hulling

- Red Lentil Hulling

- Green Lentil Hulling

- Dry Beans Hulling

- Chickpeas Hulling

- Yellow Peas Hulling

- Yellow Lentil Hulling

- Fava Bean Hulling

- Wheat Bran Removing

- Barley Hulling

- Spelt Wheat Hulling

- Buck wheat Hulling

Do you need more information?

You are always welcome to call, e-mail, or chat on WhatsApp

with our Sales Engineer Team to answer all your questions you

have in mind. We will do our utmost to revert as soon as

possible.

Saat Technologe exports to 70 countries on 4 continents. Consult any project you have in mind to benefit from our field experience. From Start-up, Turn Key Projects, to existing plant modifications; We are with you all the way.

FAQ

Saat Technologe provides 24 Months of warranty for all its Abrasive Huller, please ask your Sales Engineer for the manufacturer’s Warranty Conditions.

Saat Technologe ‘s After Sales Support Team is ready for immediate support with Phone calls, online chat, and or video calls for all your technical needs for your Abrasive Huller, You can ask for your user manual or look into your stand-by spare parts list provided by Saat Technologe.

All your questions about Abrasive Huller like Capacity variations on which conditions, best conditions, application areas, Optional features, adjustment parameters, Before and after results, yield, work principle in greater detail, assembly variations, auxiliary equipment, Electrical parameters, Why to buy from Saat Technologe, What sets Saat Technologe apart from others, references, how many of these machines have been built and working, life Span and effecting matters, Spare parts and wear and tear parts, preventative maintenance, how to handle waste, how to handle dust if any, how to adapt to your Seed business whether be Farmer, Wholesaler, importer, exporter or Retailer, the value for Money, what are included what is excluded, transport cost, installation, and training, after-sales support, warranty conditions and any other topic you may relate to your business need, always happy to assist.

Phone in Turkey

+90 0539 893 40 01