Phone in Turkey

+90 539 893 40 01

Phone in Romania

+40 744 578 303

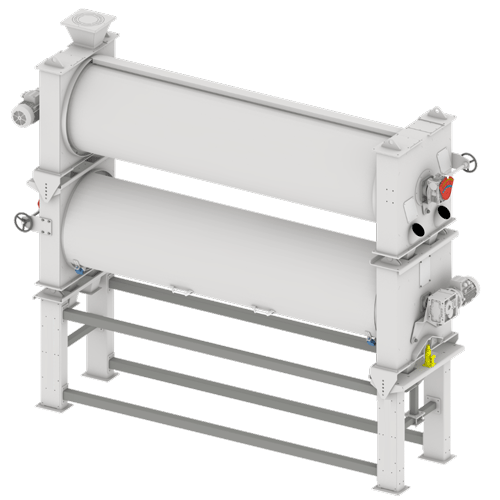

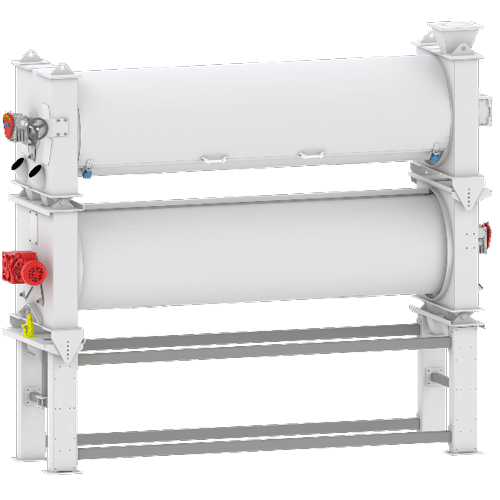

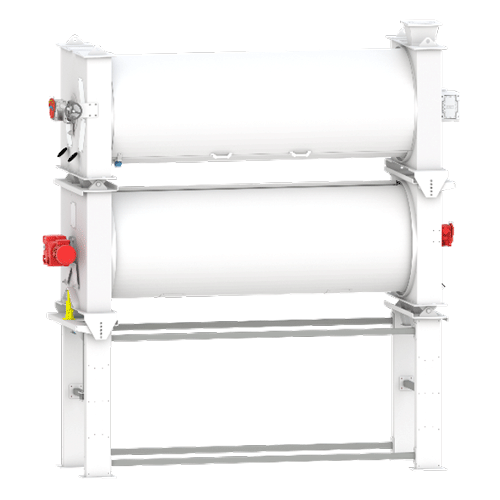

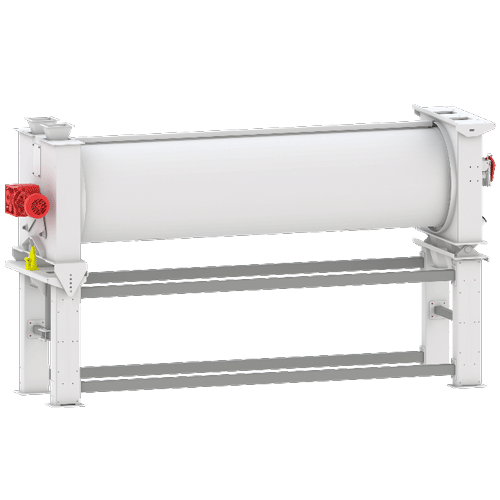

INDENT CYCLINDER SEPARATOR

Used for length grading of all granular materials, such as wheat, oat, maize, rice, fi ne seeds, lentils, sticks from sunflower or sugar beet, plastic particles, etc., as well as for the extraction of unwanted short or long admixtures.

Grading with Care.

Mechanical separation by indented cylinders is used for grading any granular material such as wheat, oats, fine seeds, lentils by length and for separating seeds from stalks and other long or short straws.

If your crops need special attention to separate foreign bodies at the cleaning stage of processing, Saat Technologe Indented Cylinders are the solution. They can be used alone or set in series to accomplish different jobs identifying different types of impurities

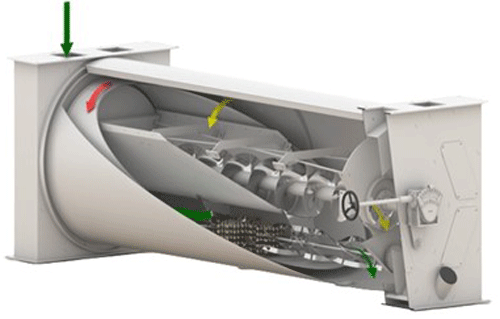

Principles of operation.

It consists of a horizontal rotating cylinder which has indents on the inside surface. Through the inlet housing, the granular material to be graded flows into the interior of the rotating cylinder. The grains that embed themselves into the indents, will be lifted, will fall into the trough (after a certain distance based on your parameters) and discharged by a conveying screw. The longer grains remain in the cylinder- shell and will be discharged separately. The size of grains can vary between 1.0 mm and 24 mm.

Construction and Function.

- 01. SHELL The inside cover is equipped with round or tear-drop shapes indents where kernel to be selected fi t precisely.

- 02. DESIGN The round, fully-closed housing is unique. Its design facilitates easy access to the cylinder segments. When the protective hood is opened, the machine is stopped automatically by a safety switch.

- 03. EXCHANGE OF SEGMENTS The cylinder shell is divided into several segments and provided with quick-release catches. This allows a simple and fast exchange of the grading segments. On request, the segments can be equipped with cleaning doors.

- SHORT PRODUCT OUTLET The grains that embed themselves into the indents, will be lifted and after a certain distance (adjustable to suit) will fall out of the pockets under gravity into the trough.

- 05. LONG PRODUCT OUTLET Kernels longer than the indent diameter will immediately slide out and remain on the inside surface of the indent cover, so to be discharged into the outlet housing.

- 06. TROUGH SEALING All separator types are sealed between the trough and the cylinder shell. This prevents unwanted grains from getting into the trough and ensures even more precise grain separation.

- 07. DRIVES No chain drives, belt drives or gearwheel drives are used in our grain separators, which guarantees considerably smoother operation. We only use top-of-the-line geared motors. Adjustable speed is offered as an option.

- 08. CHECKING THE SEPARATION Two large inspection windows on the outlet side enable the operator to check the correct setting of the separator during operation, with no risk of accident.

OPTIONAL EQUIPMENT

PNEUMATIC CLEANING A compressed-air cleaning system which ensures faster emptying of the pockets and prevents a decline in the separator’s output is available on request.

CYLINDER INCLINATION We supply adjustable inclination packages (0°-3°) or fixed inclination packages. This further optimises the separation results.

STIRRING DEVICE For heavily flowing products such as grass seeds or rice, we recommend the installation of our stirring device, which significantly increases the efficiency and output of the separator.

WEAR RESISTANT LINING For processing particularly abrasive products we can line neuralgic parts inside the machine with an exchangeable wear-resistant covering.

ADJUSTABLE SPEED Geared motors are available with mechanical or electronic speed control.

AUTOMATIC TROUGH ADJUSTMENT The trough regulation system can be equipped with adjusting motors.

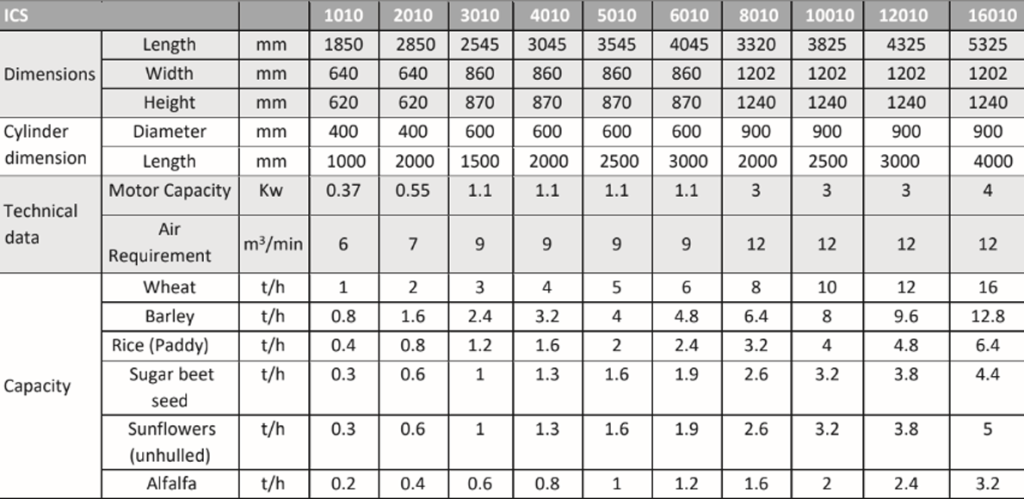

SPLITTING FEATURE By splitting the grain flow we are able to achieve an outstanding max output of 45 t/h with our separator type IC SPLITTER & SHORT & LONG SEPARATOR 16010.

Do you need more information?

You are always welcome to call, e-mail, or chat on WhatsApp

with our Sales Engineer Team to answer all your questions you

have in mind. We will do our utmost to revert as soon as

possible.

Saat Technologe exports to 70 countries on 4 continents. Consult any project you have in mind to benefit from our field experience. From Start-up, Turn Key Projects, to existing plant modifications; We are with you all the way.

FAQ

Saat Technologe provides 24 Months of warranty for all its Indent Cyclinder Separator, please ask your Sales Engineer for the manufacturer’s Warranty Conditions.

Saat Technologe ‘s After Sales Support Team is ready for immediate support with Phone calls, online chat, and or video calls for all your technical needs for your Indent Cyclinder Separator, You can ask for your user manual or look into your stand-by spare parts list provided by Saat Technologe.

All your questions about Indent Cyclinder Separator like Capacity variations on which conditions, best conditions, application areas, Optional features, adjustment parameters, Before and after results, yield, work principle in greater detail, assembly variations, auxiliary equipment, Electrical parameters, Why to buy from Saat Technologe, What sets Saat Technologe apart from others, references, how many of these machines have been built and working, life Span and effecting matters, Spare parts and wear and tear parts, preventative maintenance, how to handle waste, how to handle dust if any, how to adapt to your Seed business whether be Farmer, Wholesaler, importer, exporter or Retailer, the value for Money, what are included what is excluded, transport cost, installation, and training, after-sales support, warranty conditions and any other topic you may relate to your business need, always happy to assist.

Phone in Turkey

+90 0539 893 40 01

Phone in Romania

+40 744 578 303