Phone in Turkey

+90 539 893 40 01

Phone in Romania

+40 744 578 303

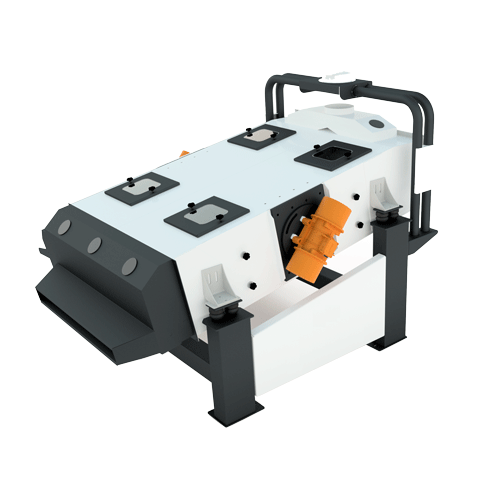

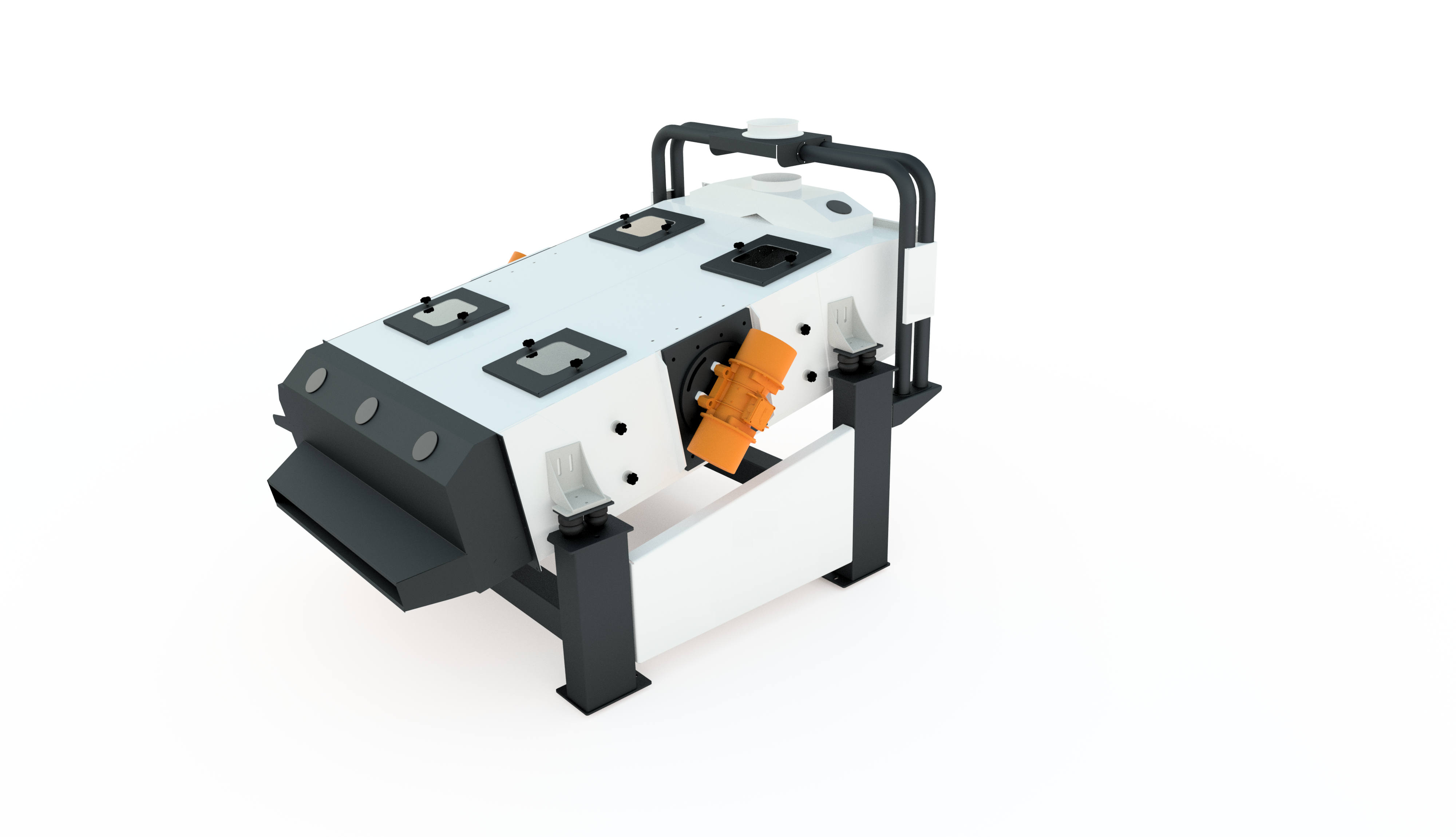

VIBROTARY SEED PRE-CLEANERS

For more than 15 years, Saat Technologe has been something of a fixed institution in the development, design and production of cleaning and grading machines. Throughout the decades, we have left a significant impact on the technical standard of these systems. Especially when it comes to harvest crop intake systems as well as pre-cleaning and main cleaning systems for cereal grains, maize, oilseeds, legumes, malt, rice, coffee and soybeans a wide range of users are relying on technology made by Saat Technologe. Our high-performance machines are used mainly in

- Harvest crop intake and receipt facilities delivery pre-cleaning operations

- Mills and malting plants / Silos and storage warehouses / Seed processing plants

Wide range of applications Saat Technologe VIBRA Separator is implemented in separation of Oversize and Undersize admixtures from seed lot in…

- Grain; wheat, durum, corn/maize, rye, soybean, oat, buckwheat, spelt, millet, and rice mills for basic cleaning

- Pulse; beans, lentil, chickpea, pigeon pea, yellow pea, vetch for basic cleaning

- Spices; cumin, coriander, mustard, Caraway, black pepper, Clover and Fennel for basic cleaning

- Oil Seeds; sesame, sunflower seed, pumpkin seed, flex, pistachio, rape, saower for basic cleaning or in bulk storage systems for pre-cleaning.

- In addition, the machine is also successfully used in animal feed production plants, seed treatment systems, oilseed cleaning installations, and cocoa bean grading systems.

- In addition, it grades a wide variety of products by size.

- Efficient grain cleaning at high throughput rates

- Using a screen separation system, the Separator VIBRA separates the grain from coarse impurities such as oversize grains, strings, straw, wood, stones and pebbles, or clods of earth plus fine impurities such as sand or broken grains.

- The VIBRA achieves high throughputs up to 24 t/h in cleaning applications and 100 t/h in pre-cleaning applications in bulk storage installations.

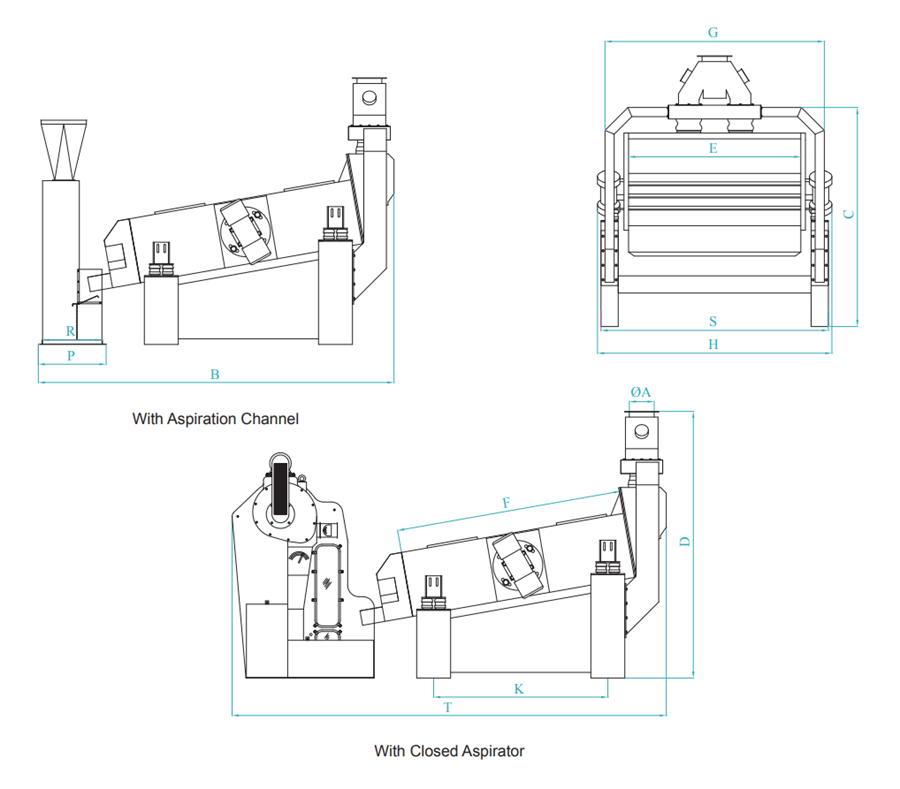

- As an option, it is possible to install a downstream aspiration channel or air-recycling aspirator in order to separate low-density particles such as dust, hull particles, or husks and thus to optimize the cleaning result.

Advantages

- Drive by electric vibratory motors for negligible maintenance and highly effective screening.

- Choice of aspiration systems from basic aspiration case to high performance pneumatic channels, as follows:

- Version “A” – separator with basic aspiration case – for removal of dust.

- Version “B” – blower located below the sieve basket in separator frame to blow dust of cleaned product.

Application

The fact that the stroke, the angle of throw and the screen inclination of the VIBRA “SEPARATOR” are adjustable, allows this separator to be used for an exceptionally large variety of applications, for instance:

— cleaning applications in storage elevators (silos), flour mills, seed treatment plants, malthouses, feed mills, etc.

— sizing of various seed products, coffee, etc.

— classification of by-products.

Features

— Free-swinging sieve with unidirectional screen motion, supported on hollow rubber cylinders

— Drive by means of vibrators located in the centre of gravity of the machine

— Screen inclination pre-set at the works, made to suit the place of application, adjustment to between 20 and 120

— For special applications: with continuously variable screen slope adjustment, from 20 to 60

— Adjustable angle of throw

— Adjustable stroke

Please see Catalogue and Data Sheet of VIRA Screen Separator for Technical and Capacity Charts

Do you need more information?

You are always welcome to call, e-mail, or chat on WhatsApp

with our Sales Engineer Team to answer all your questions you

have in mind. We will do our utmost to revert as soon as

possible.

Saat Technologe exports to 70 countries on 4 continents. Consult any project you have in mind to benefit from our field experience. From Start-up, Turn Key Projects, to existing plant modifications; We are with you all the way.

FAQ

Saat Technologe provides 24 Months of warranty for all its Vibrotary Seed Pre-Cleaners, please ask your Sales Engineer for the manufacturer’s Warranty Conditions.

Saat Technologe ‘s After Sales Support Team is ready for immediate support with Phone calls, online chat, and or video calls for all your technical needs for your Vibrotary Seed Pre-Cleaners, You can ask for your user manual or look into your stand-by spare parts list provided by Saat Technologe.

All your questions about Vibrotary Seed Pre-Cleaners like Capacity variations on which conditions, best conditions, application areas, Optional features, adjustment parameters, Before and after results, yield, work principle in greater detail, assembly variations, auxiliary equipment, Electrical parameters, Why to buy from Saat Technologe, What sets Saat Technologe apart from others, references, how many of these machines have been built and working, life Span and effecting matters, Spare parts and wear and tear parts, preventative maintenance, how to handle waste, how to handle dust if any, how to adapt to your Seed business whether be Farmer, Wholesaler, importer, exporter or Retailer, the value for Money, what are included what is excluded, transport cost, installation, and training, after-sales support, warranty conditions and any other topic you may relate to your business need, always happy to assist.

Phone in Turkey

+90 0539 893 40 01

Phone in Romania

+40 744 578 303