Phone in Turkey

+90 539 893 40 01

Phone in Romania

+40 744 578 303

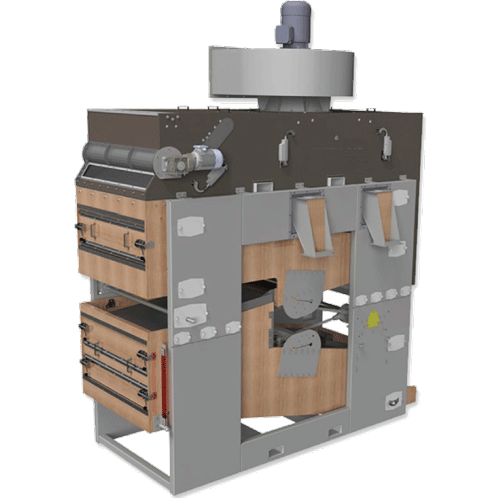

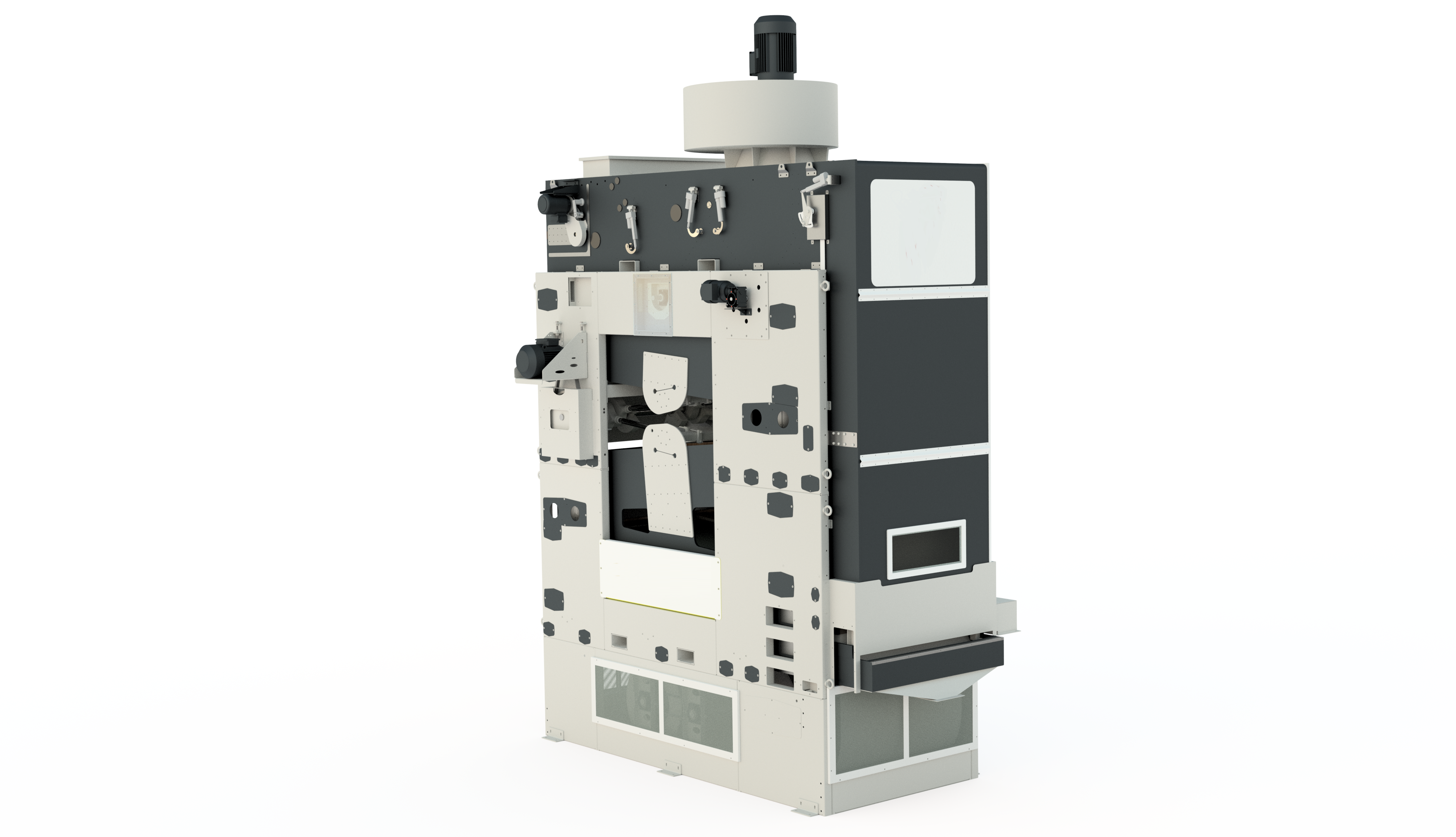

FLAT SCREEN SEED PRE-CLEANERS

OPTIMIUM SEED PRE-CLEANERS 240 SERIES FLAT SCREEN TYPE

Saat Technologe develops and manufactures solutions for pre-cleaning of all cereals, maize, rape seed, peas and similar

seeds for before drying, storage or Processing. Pre-cleaning differs from rough cleaning in the way that this process also is able to separate admixtures smaller, larger and lighter than the main seed.

The Saat Technologe product range covers Saat Technologe OPTIMUM Pre-Cleaners that come in Flat Screen Types, Rotary Drum Types, Oscillating Types and Vibratory Type Screen Cleaners.

Saat Technologe Flat Screen OPTIMUM Seed Pre-Cleaners are a versatile screen cleaner specifically designed for pre cleaning using a 5 – 15m² area in conjunction with a sophisticated aspiration system.

Pre-cleaning may replace rough cleaning when receiving a raw material from which, in addition to the large impurities, most of the sand, thin grain and weeds are to be separated. Pre-cleaners have capacities ranging from 5 to 100t/h. All these cleaners have effective pre-suction and after suction systems for separation of light products such as chaff, straw, light grain, etc

OPTIMIUM PRE-CLEANERS DISTINGUISHING FEATURES

- FULL-WIDTH SHAKER FEEDER

- Has infinitely variable adjustment of the feed capacity via a separate control panel.

- Ensures uniform flow over the entire width of screen.

- Considerably improves air cleaning. Since the product hits the pre-suction area in a uniform manner.

- Is Self-cleaning

- Is Gentle with Respect to Leguminous Seeds, Paddy Rice Etc.

- Ensures Optimum Capacity Utilisation of the machine

- Ensures no downtime due to blocked Inlets

- Requires no cleaning when changing products

- FEED ROLLER

- Has an adjustable capacity shutter in combination with infinitely variable speed control of the feed roller which controls the feed capacity.

- Is not affected by light weight waste material and large impurities such as stones etc.

- Has a built-in spring-loaded safety device which protects the feed roller against da-mage.

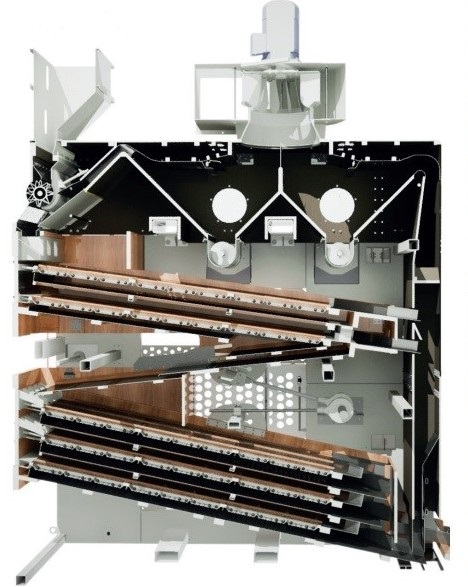

- PRE-SUCTION & POST SUCTION SYSTEM

- Built as two separate air suction units.

- Can be connected to existing central aspiration systems. Due to the small air volume.

- SCREW AUGER OUTLET for LIGHT REJECT

- Ensures Continuous Discharge of dust and waste from the air system via screw conveyors

- Has finger flaps to ensure optimal dust separation in the expansions chamber by preventing false air from entering the chamber

- SCREEN BOXES PLYWOOD SWEDOTEX FILM

- Are moisture-resistant and Insect-resistant. And approved by the food industry

- Are constructed with replaceable wear plates and screen runners in exposed areas

- Have a long lifetime due to the fact that the plywood easily copes with the vibrations of the screen box

- Give less resonance owing to the use of plywood, Thus resulting in a better working environment.

- DISTRIBUTOR

- Ensures 50% Distribution of the grain flow via the top and bottom screen boxes respectively

- 50% and 33% distributors ensure distribution of the grain flow in each screen box between various screen rows.

- ACCSESS to the SCREENS

- The access hatches have snap-action locks

- The hatches are small and hinged at the bottom

- Rapid changing of screens

- CHANGE OF SCREEN INCLINATION

- Allows Different Capacity and Cleaning Result.

- Ensures Excellent Purity and Minimum Waste

- Is Easily Carried Out by Changing the Screen Hangers.

- The Machine can be used as A Pre-cleaner, Industrial Cleaner or Fine Cleaner

- OPTIMUM SCREENS FOR ALL PURPOSES

- Are Available with Round and Oblong Holes From 0.3 To 25.0 Mm

- Are Also Available as Wire-mesh Screens for Special Products

- Have As Standard Holes in The Screen Plates with Very Small Tolerances, Thus Ensuring Minimum Cleaning Loss

- Are Available in A Standard Size Of 1000 Mm (L) X 1800 Mm (W) = 1.8 M2, Which Can Be Used in All OPTIMUM Cleaners, Thus Reducing the Number of Screens Required

- BALL BOX

- Ensures Efficient Cleaning of Screens by Means Of Rubber Balls Which Are Food- Grade Approved

- Can Maintain the Cleaning Effect at Extremely Low Temperatures As The Rubber Balls Are Moulded in A Material

- Particularly Well-suited to The Task

- Is Cast in One Piece in Order to Prevent Trapped Seeds, Etc.

- (Self-cleaning)

- Is Separately Mounted in The Screen Box, Which Enables A Quick Change of Screens Without Removing the Ball Boxes

- BALANCED ECCENTRIC SYSTEM

- Is Fitted with Counterweights That Ensure Smooth Running

- Results In Minimum Stress on Buildings And Steel Structures

- Is Fitted With »heavy Duty« Bearings

- Ensures Maximum Utilisation of The Cleaning Effect of The Screens Owing to Care- Fully Matched Stroke and Speed Of

- Rotation

- SUSPENSION OF SCREEN BOXES

- The Screen Boxes Are Suspended in Rosta Suspension Units With Moveable Parts in Rubber

- Prevents Transmission of Vibrations to Buildings and Other Machines

- Ensures That the Machine Can Be Located Almost Any-

- Where Without Expensive Foundations Needing to Be Established

- Balancing Of the Dynamic Forces in The Machine Ensures Extended Operation Without Repair

- TOTALLY INCLOSED CLEANERS

- The Cleaners Are Totally Closed

- The Doors Are an Integral Part of The Waste Pipe System

- Easy And Rapid Access to Replace Outlet Trays When Changing Flow

- MOTORS

- Are Mounted Externally, Thus Resulting In Rapid And Simple Adjustment and Replacement Of The V-belts

- COVERING OF SCREEN SECTIONS

- Both Screen Sections Are Covered with Galvanised Plate With Rubber Inspection Hatches

- There Is Dust Extraction from Each Screen Box

- WEAR PLATES

- Replaceable Pehd 1000 And Hardox Wear Plates Are Located At All Exposed Surfaces

- Easy To Replace

- Repair Intervals Are Extended

- Repair Costs Are Reduced

- Are Moisture-resistant And Insect- Resistant, And Approved By the Food Industry

- Are Constructed with Replaceable Wear Plates And Screen Runners in Exposed Areas

- Have A Long Lifetime Due to The Fact That the Plywood Easily Copes with The Vibrations of The Screen Box

- Give Less Resonance Owing to The Use of Plywood, Thus Resulting In a Better Working Environment

- SAMPLING

- Handy Sampler

- Easy To Take Samples from The Various Outlet Trays

- RECIRCULATING POST-SUCTION UNIT

- Ensures The Highest Purity of The Product by Means Of The Extraction of Lightweight Particles Such as Empty

- Kernels, Husks and Dust, Etc. When The Product Exits The Cleaner Via the Exhaust Unit

- EXHAUST UNIT FOR CLEAN PRODUCT

- Distributes The Recirculated Air So That All Clean Product Is Aerated

- The Remaining Lightweight Kernels and Dust Particles Are Separated

- Fresh Air is Supplied at The Same Rate as The Air That is Removed in the Mini-cyclone

Do you need more information?

You are always welcome to call, e-mail, or chat on WhatsApp

with our Sales Engineer Team to answer all your questions you

have in mind. We will do our utmost to revert as soon as

possible.

Saat Technologe exports to 70 countries on 4 continents. Consult any project you have in mind to benefit from our field experience. From Start-up, Turn Key Projects, to existing plant modifications; We are with you all the way.

FAQ

Saat Technologe provides 24 Months of warranty for all its Flat Screen Seed Pre-Cleaners, please ask your Sales Engineer for the manufacturer’s Warranty Conditions.

Saat Technologe ‘s After Sales Support Team is ready for immediate support with Phone calls, online chat, and or video calls for all your technical needs for your Flat Screen Seed Pre-Cleaners, You can ask for your user manual or look into your stand-by spare parts list provided by Saat Technologe.

All your questions about Flat Screen Seed Pre-Cleaners like Capacity variations on which conditions, best conditions, application areas, Optional features, adjustment parameters, Before and after results, yield, work principle in greater detail, assembly variations, auxiliary equipment, Electrical parameters, Why to buy from Saat Technologe, What sets Saat Technologe apart from others, references, how many of these machines have been built and working, life Span and effecting matters, Spare parts and wear and tear parts, preventative maintenance, how to handle waste, how to handle dust if any, how to adapt to your Seed business whether be Farmer, Wholesaler, importer, exporter or Retailer, the value for Money, what are included what is excluded, transport cost, installation, and training, after-sales support, warranty conditions and any other topic you may relate to your business need, always happy to assist.

Phone in Turkey

+90 0539 893 40 01

Phone in Romania

+40 744 578 303