Phone in Turkey

+90 539 893 40 01

Phone in Romania

+90 0539 893 40 01

WHEAT & BARLEY SEED LINES

Saat Technologe with 40 years of field experience on Seed Cleaning/Conditioning and Processing Industry in several parts of the World with thousands of clients and Project has a unique approach to all types of challenges.

We understand the importance of save and good food for human consumption and always working together with growers to improve the grain handling and processing.

At Saat Technologe, we have a large range of Seed Processing solutions so we try to find the best out fit for clients process/ business needs.

We understand the growing population need and suppliers requirements in this changing climate and world. We do our up most to be a head of Industry needs.

With Certified Seed Regulations, we have supplied countless number of Field Seed Processing lines with in our territory in Turkey, Azerbaijan, Uzbekistan, Turkmenistan, Iraq, Egypt, Algeria, Greece, Ukraine, Romania and Spain.

What is seed processing?

After harvesting, seeds are threshed, dried, cleaned and tested before being stored and distributed to farmers for planting. Newly harvested and threshed seeds from the field often contain undesirable materials (e.g. stems, leaves and chaff; stones and soil particles; weed seeds and other unwanted seeds). It is essential to remove impurities to obtain good quality pure seed of the required crop and variety.

Seed processing or seed conditioning is the preparation of harvested seed for marketing to farmers. The processes involved include drying, threshing, pre-cleaning, cleaning, size grading, treating, quality testing, packaging and labelling.

PRINCIPLES OF SEED PROCESSING

Within the seed lot, both the pure seeds and any undesirable materials may present major differences in physical properties:

- size (length, width, thickness)

- shape

- weight/density

- texture (rough, smooth, pointed)

- colour

The seed-cleaning operation exploits these differences to separate the desired seed from the contaminants. However, the seeds of the required end product may not be uniform, including big and small, long and short seeds. Moreover, seeds and contaminants (e.g. weeds) without sufficiently different physical characteristics are not easily separated.

No single machine is capable of separating seeds on the basis of all the physical properties listed above. A variety of cleaning machines and equipment exist to separate seed according to specific physical characteristics.

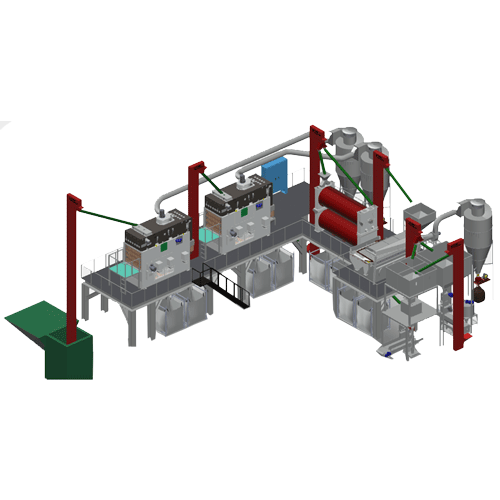

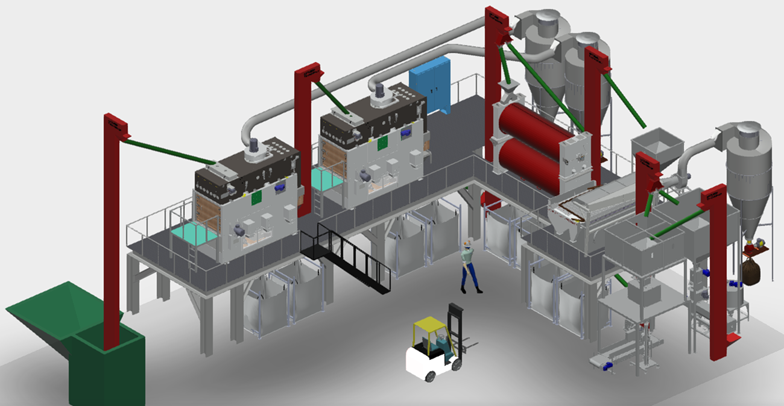

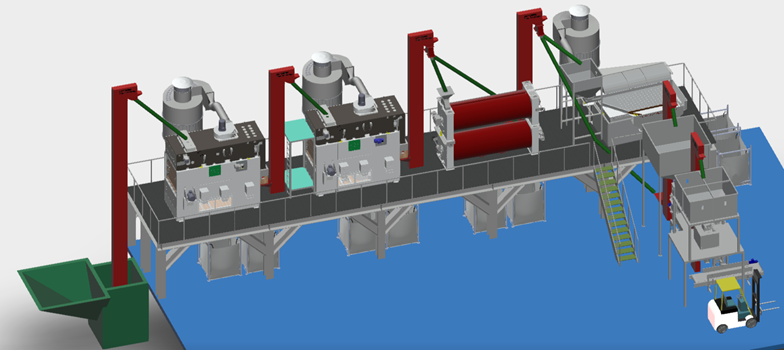

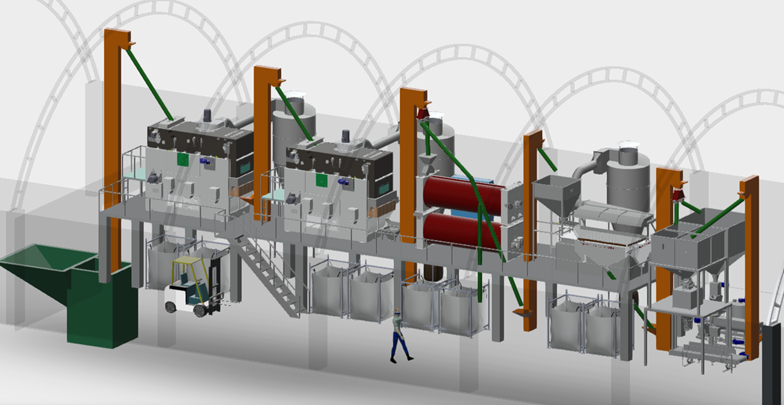

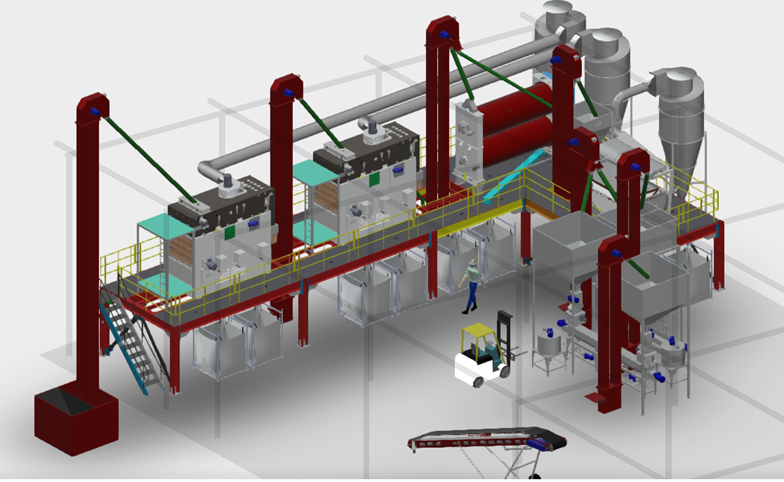

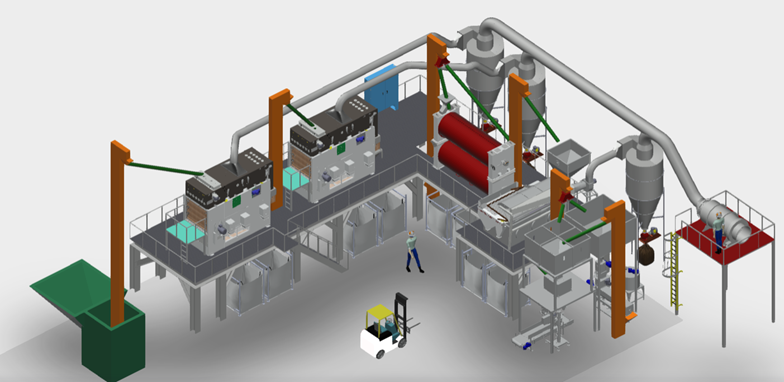

Please review some of our installations below.

Do you need more information?

You are always welcome to call, e-mail, or chat on WhatsApp

with our Sales Engineer Team to answer all your questions you

have in mind. We will do our utmost to revert as soon as

possible.

Saat Technologe exports to 70 countries on 4 continents. Consult any project you have in mind to benefit from our field experience. From Start-up, Turn Key Projects, to existing plant modifications; We are with you all the way.

FAQ

Saat Technologe provides 24 Months of warranty for all its Wheat & Barley Seed Lines, please ask your Sales Engineer for the manufacturer’s Warranty Conditions.

Saat Technologe ‘s After Sales Support Team is ready for immediate support with Phone calls, online chat, and or video calls for all your technical needs for your Wheat & Barley Seed Lines, You can ask for your user manual or look into your stand-by spare parts list provided by Saat Technologe.

All your questions about Wheat & Barley Seed Lines like Seed Proces, Pre-Engineering, Project Management, Installation and Commissioning, Training, Plant Automation, Turnkey Partner Services and Management Information Systems will be answered by Saat Technologe Sales Engineer please visit our Services Webpage to get an overview.

Phone in Turkey

+90 0539 893 40 01

Phone in Romania

+40 744 578 303